How to Get a Dull Knife Sharp Again

Knives are a common fixture in our everyday lives, be it in the kitchen, workplace or the dandy outdoors. What is fairly uncommon however, is someone who knows how to continue their knife precipitous and how to discern what "sharp" actually is. Hopefully this article volition assist to divulge a few secrets to the mystery that is making and keeping a pocketknife abrupt.

Knives are a common fixture in our everyday lives, be it in the kitchen, workplace or the dandy outdoors. What is fairly uncommon however, is someone who knows how to continue their knife precipitous and how to discern what "sharp" actually is. Hopefully this article volition assist to divulge a few secrets to the mystery that is making and keeping a pocketknife abrupt.

While there are extreme lengths one can become to in chasing the ultimate precipitous edge on their EDC, this tutorial will teach you how to keep a good working border on almost any cutlery.

At that place are a few steps to this system, simply with some do, care and attending being paid; anybody should be able to finer sharpen their knives using this method with very picayune invested for the results accomplished. The organization is comprised of the following steps.

>>Hither'south the best low cost sharpening tool you'll e'er need<<

Assess the damage

Discerning what impairment has occurred to the edge is a revealing outset step. Looking at the knife edge from both the side, and caput on will show what kinds of damage has happened.

When looked at from the side you can run across small breaks in the line that makes upward the very edge of the knife, these are either rolls, or chips… both of which you volition be removing. The depth of the chips taken out of the bract will indicate how much metallic along the entire edge you lot volition have to remove to keep the same general shape of your pocketknife.

When looked at from the side you can run across small breaks in the line that makes upward the very edge of the knife, these are either rolls, or chips… both of which you volition be removing. The depth of the chips taken out of the bract will indicate how much metallic along the entire edge you lot volition have to remove to keep the same general shape of your pocketknife.

As well looking at how thick backside the border itself your pocketknife is would be a adept thought at this time, if your blade has been binding a lot in material later on a few sharpenings and isn't cutting as effortlessly as information technology once used to then chances are it needs a scrap of thinning out behind the edge.

De-stressing the metal

The very outset step is called de-stressing the edge. The steel at the edge of your dull knife is weak and substantially ruined from the abuse it's received over time. Information technology's important to become rid of this damaged steel in order to reveal the fresher, stronger steel that lies beneath.

To do this you must take the knife and depict it through your sharpening stone which volition blunt the edge, besides as expose skillful steel. Hold the border perpendicular to the stone when doing this and use very, very low-cal pressure level.

Determine your sharpening angle

This next step involves finding what angles to sharpen at if you don't have whatever specific tools for doing so. You tin can test how thick or thin your pocketknife needs to be based on your ain use and how it ends up after you initially sharpen it, but for now allow's outset at 15 degrees per side.

How do yous measure 15 degrees? Accept a piece of paper, each corner is a ninety caste angle, if you lot fold that bending at the corner in to thirds you volition accept a wedge that is a full of 30 degrees. Half of that is fifteen degrees. This will be the angle you want to hold your knife against the stone while thinning out behind the edge and creating a bevel.

How do yous measure 15 degrees? Accept a piece of paper, each corner is a ninety caste angle, if you lot fold that bending at the corner in to thirds you volition accept a wedge that is a full of 30 degrees. Half of that is fifteen degrees. This will be the angle you want to hold your knife against the stone while thinning out behind the edge and creating a bevel.

Use the sharpening stone

To start brainstorm abrading the total length of the edge forth a coarse rock (well-nigh 220-350 grit is probably fine) which is relatively flat. I recommend doing an even amount of strokes on each side if the bevels are already equal, otherwise you will have to use your better judgment as to how much steel must exist removed to make the bevels equal.

Start out by making sweeping strokes using as much area of the rock as possible and working in sections equally necessary, making certain to maintain the same angles fifty-fifty at the tip, and making sure not to let the tip of the knife slide off of the rock, this can cause rounding or fifty-fifty chipping of the tip of the blade. Relatively calorie-free pressure is all yous should need, with the stone doing much of the work.

Start out by making sweeping strokes using as much area of the rock as possible and working in sections equally necessary, making certain to maintain the same angles fifty-fifty at the tip, and making sure not to let the tip of the knife slide off of the rock, this can cause rounding or fifty-fifty chipping of the tip of the blade. Relatively calorie-free pressure is all yous should need, with the stone doing much of the work.

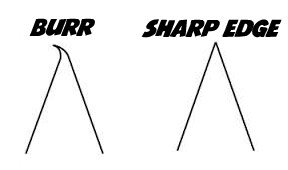

Somewhen you'll know when to stop at this stage on both sides earlier creating a "burr", just for at present just abrade material until on the other side of the blade there is a tiny burr adult.

A burr is a thin strip of abraded metal which accumulates on the side of the bract contrary the one you've been grinding on. You tin can generally slide your fingernail off the edge and the burr will scratch your nail. Once the burr is created on i side, elevate the knife through a piece of wood a few times to knock the burr off or reduce it, and and so ensure the aforementioned is achieved on the other side (developing and removing a burr).

A burr is a thin strip of abraded metal which accumulates on the side of the bract contrary the one you've been grinding on. You tin can generally slide your fingernail off the edge and the burr will scratch your nail. Once the burr is created on i side, elevate the knife through a piece of wood a few times to knock the burr off or reduce it, and and so ensure the aforementioned is achieved on the other side (developing and removing a burr).

By and large a burr is inevitable but equally you improve your skills you should be able to get to the point where you're creating merely a super fine burr which yous tin't really see or feel. In creating a sizable burr and removing it, the metal on the very edge of the pocketknife may exist pretty abrupt, but also extremely weak. This metallic has been stressed past beingness bent dorsum and forth besides as having the burr ripped off. The steel on the edge has fallen victim to the same properties that occur when you bend a spoon back and forth many times, the metal weakens until it merely breaks. At that point you'd accept to de-stress the edge still again to get rid of this weaker steel and y'all're basically back to where you started.

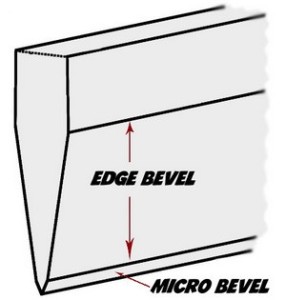

Now you should have a chiefborder bevel with which to work. You can enhance the grit of stones and exercise higher polishes if y'all wish from here.

Applying the micro bevel

Once the chief edge bevel has been created, you volition take to apply a micro bevel. This is the office of the "edge" that is doing the actual cutting. The bevel portion is simply at that place to be thin and look pretty. The micro bevel volition also serve to remove whatsoever fine burr still left over from the previous stride.

Once the chief edge bevel has been created, you volition take to apply a micro bevel. This is the office of the "edge" that is doing the actual cutting. The bevel portion is simply at that place to be thin and look pretty. The micro bevel volition also serve to remove whatsoever fine burr still left over from the previous stride.

To apply the micro bevel to the main edge you've already created, accept ane of the more coarse stones y'all'd used when making the edge bevel, and brainstorm with that.

Using strokes beyond the whole if non most of the bract, make edge leading strokes at a slightly higher bending than the i you'd used to create your edge bevel. This marginally wider border makes for a stronger cut border, thus increasing overall border memory.

For nigh people 20 degrees is ideal, simply just raising the spine of the blade a hair above that bending guide made in earlier stride works just fine.

Making alternating strokes keep the edge of the blade as perpendicular to the movement you make across the stone, so the scratch blueprint goes perpendicular to the orientation of the edge itself, if non turned towards the handle a bit, this will leave an edge which will cut ameliorate in tasks where the knife is slicing in a pull cut, which is most mutual. Super lite strokes here folks!

Making alternating strokes keep the edge of the blade as perpendicular to the movement you make across the stone, so the scratch blueprint goes perpendicular to the orientation of the edge itself, if non turned towards the handle a bit, this will leave an edge which will cut ameliorate in tasks where the knife is slicing in a pull cut, which is most mutual. Super lite strokes here folks!

Afterwards a skillful amount of alternating strokes you should experience an edge adult, keep checking and making lighter and lighter strokes, and increasing the fineness of the stones you're using if possible.After this step you should accept a pretty nice working border, but you lot can take it a bit finer if y'all'd like.

Stropping

Stropping an edge is generally the final footstep, information technology volition strop (and sometimes sharpen if you use abrasives on your strop) an border and align the teeth created by the scratches from the stone this tin be done with a piece of flat cardboard, paper, blue jeans, or commonly a leather belt (though using a proper strop is recommended if available).

Instead of using edge leading strokes as though yous're trying to shave off a piece of whatever y'all're doing them to (the sharpening stones) instead you will drag the edge backwards over the strop, alternating sides with each stroke and using a light touch, this volition leave the border performing just a little meliorate than information technology did before, with a higher level of keenness.

Instead of using edge leading strokes as though yous're trying to shave off a piece of whatever y'all're doing them to (the sharpening stones) instead you will drag the edge backwards over the strop, alternating sides with each stroke and using a light touch, this volition leave the border performing just a little meliorate than information technology did before, with a higher level of keenness.

If you'd like to take it a step further, you can apply whatsoever number of abrasives to your "strop" and they will refine the edge even farther, while it's generally non necessary for near every day cutting tasks, it tin can be fun to run into just how far you can take your edge sharpness. Experiment with varying abrasives on your hone and see what works best for y'all and the knives you have.

With technique and patience you'll be able to produce insanely sharp blades.

Maintaining your edge

Subsequently a while your knife will go ho-hum once once again. I don't care if you have the best premium steels out in that location, information technology's but going to happen eventually. Depending on how far you let it get, it will either demand a low-cal affect up, or totally re-doing the whole process again.

In general I recommend almost average users maintain the xv degree per side edge bevel, merely if you lot're finding your edges aren't going irksome at all, you can actually just keep the xv degrees per side bevel and strop that adjacent time, just keeping it thinned out instead of making a micro bevel. This volition improve performance past a huge degree, but volition leave an edge which may not last as long.

Conversely, if you find your edge is going deadening faster than you'd like, raising the angle a bit more when putting on a micro bevel should help remedy this situation. Either mode, unless your blade is actually beat up, you lot should be able to maintain your knives without thinning them out again for a reasonable amount of time, and just putting on a micro bevel and stropping the blade. One time the knife isn't cutting very well, just repeat all the steps over again and you'll be back in business.

Recommended equipment

Then what equipment do I recommend? Well, first thing to bespeak out is that success with sharpening is probably about lxxx% technique and only 20% tools. With that said, here's my advice.

In terms of the abrasives, I recommend DMT Sharpeners which simply piece of work the best on every type of steel in the general sense. They are the hardest textile and will even cut the carbides of a steel, allowing for the new super steels to concur an even sharper edge than previously idea when sharpening them on natural stones.

In terms of the abrasives, I recommend DMT Sharpeners which simply piece of work the best on every type of steel in the general sense. They are the hardest textile and will even cut the carbides of a steel, allowing for the new super steels to concur an even sharper edge than previously idea when sharpening them on natural stones.

Natural stones like Arkansas stones are nice and work well on more basic steels, simply on super steels with high carbides they simply stress the metal surrounding the carbides more they should and cause them to fall out of the steel matrix.

Japanese water stones are nice for making border bevels, just for the border itself the slurry they can build will leave a rounded and blunt edge when using an edge leading stroke. This is why I recommend making the edge bevel with exclusively border trailing strokes on this type of stone.

The Spyderco Sharpmaker (Amazon) is really prissy for keeping upwards on maintenance of a knife'southward micro bevel, just for heavy work such equally thinning out a bract consider the DMT sharpener. With the optional diamond rods the Sharpmaker system becomes much more than versatile, especially when lots of material needs removal.

Well, that'due south it folks. Stay Sharp!!

Source: https://knifeinformer.com/how-to-get-your-knives-razor-sharp/

0 Response to "How to Get a Dull Knife Sharp Again"

Post a Comment